Individual solutions for your company

Engineering

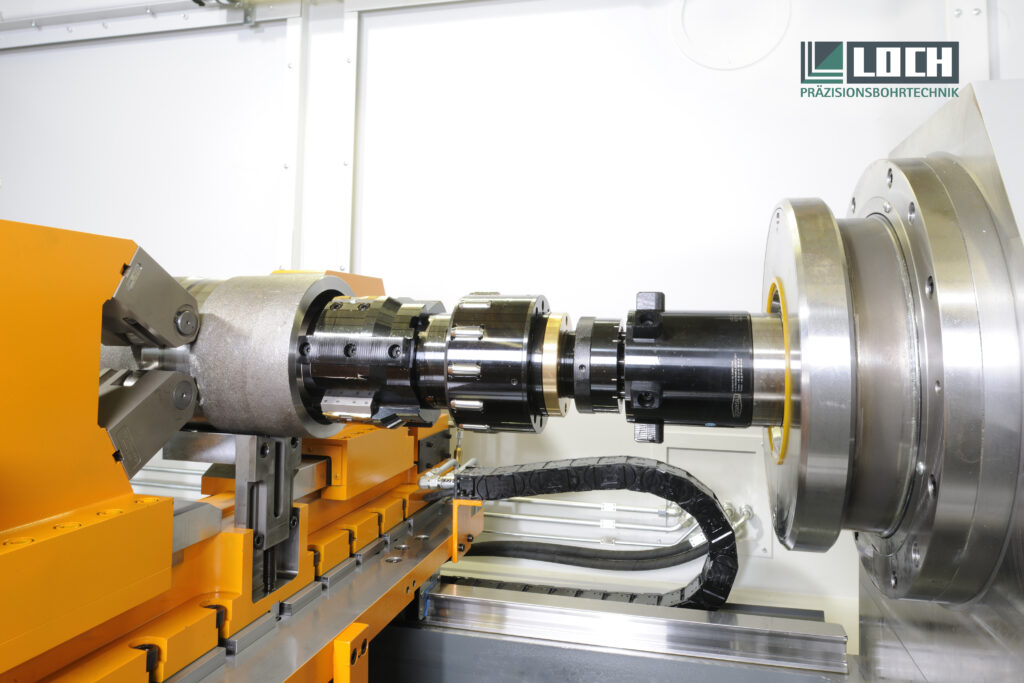

Whether it’s ELB- or BTA- machines, whether it’s single-spindle or multi spindle, whether configurated with automatic loading or configurated with automatic tool changer – machines of Loch Präzisions Bohrtechnik GmbH are up to your offer!

Through quality made in Germany, precision in depth and fully automated machines we improve your production sustainably and offer you the best cost-benefit ratio!

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von Vimeo.

Mehr erfahren

Deep Hole Drilling Machine TB1

Deep hole drilling machine TB1 / TB2

Deep hole drilling machine TB2/TB4

Cylinder processing machine

Co-ordinate deep hole drilling machine

Deep hole drilling plants

Übersicht

Tiefbohrmaschine TB1

Tiefbohrmaschine TB1/TB2

Tiefbohrmaschine TB2/TB4

Zylinder-bearbeitungs-maschine

Koordinaten-Tiefbohrmaschine

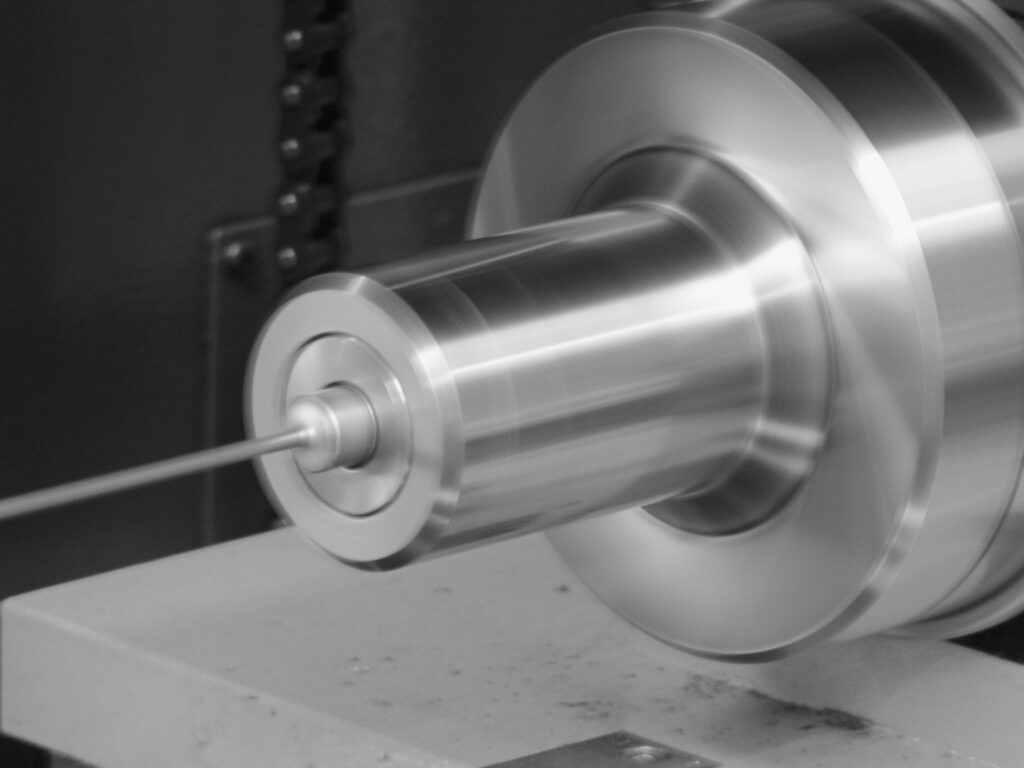

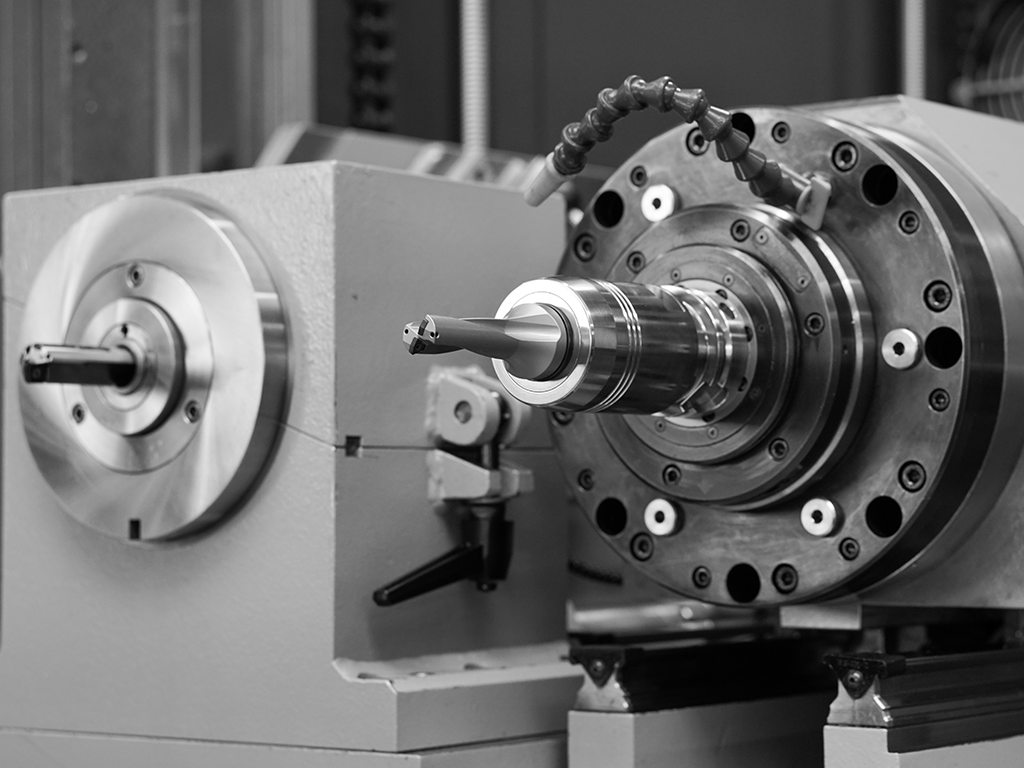

Deep hole drilling machines type TB1 / TB2

1-axis machines for the production of smaller and medium drilling diameters. The machines can be produced in horizontal and vertical design. The drilling unit can be implemented independently from the side of the workpiece.

More-spindle configuration available: 1 / 2 / 3 / 4 and 6-spindle!

01 Production system

ELB / BTA

02 Production method

- Stationary tool, rotating workpiece

- Turning tool, stationary workpiece

- Turning tool, counter-rotating workpiece

03 Diameter range

1 – 80 mm

04 Drilling depth

Up to 4000 mm

05 Optional available

- A conversion kit for honing

- A conversion kit for bottle boring

- A conversion kit for skipping and roller burnishing

- Configuration for automatic loading and unloading

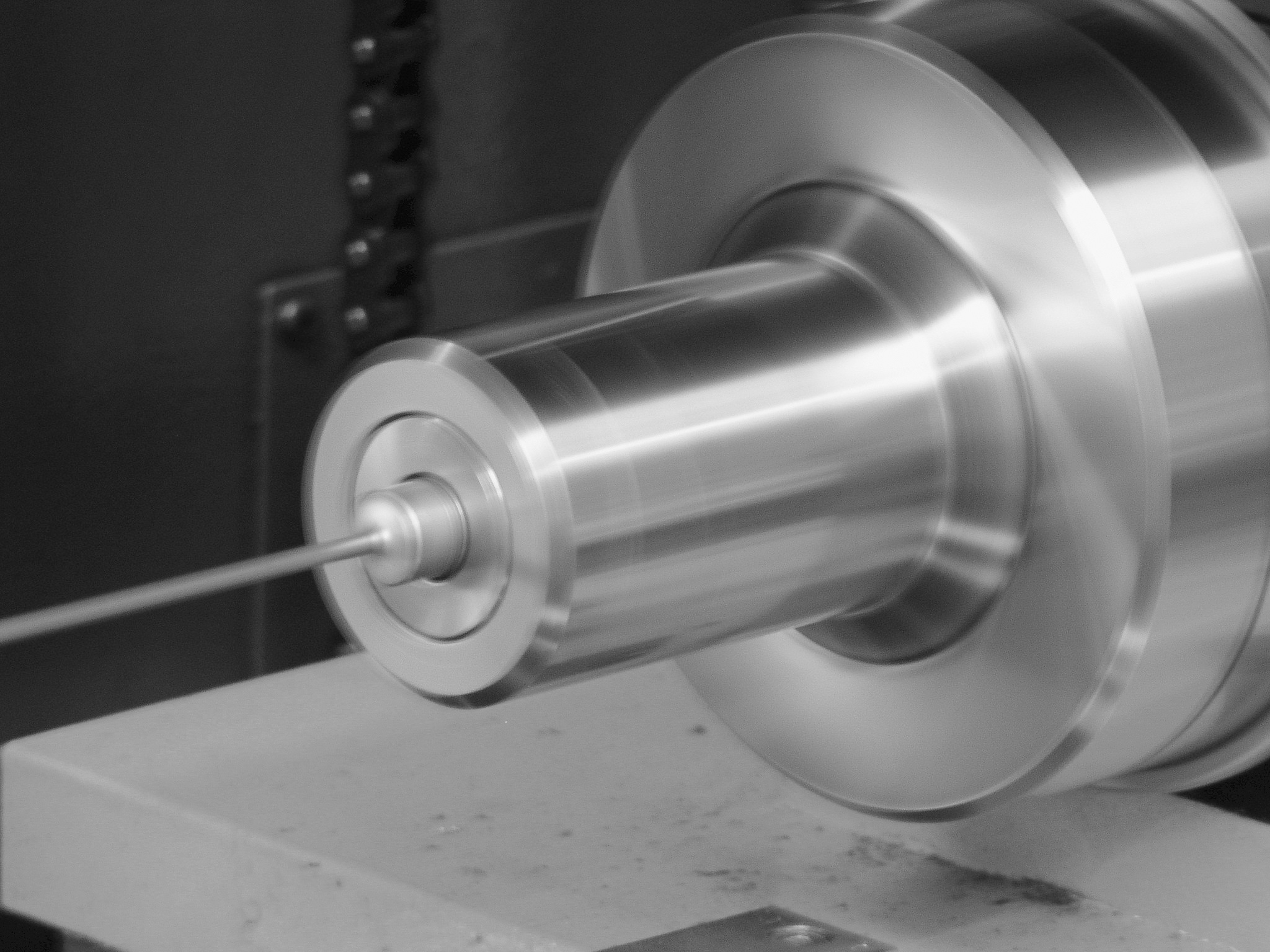

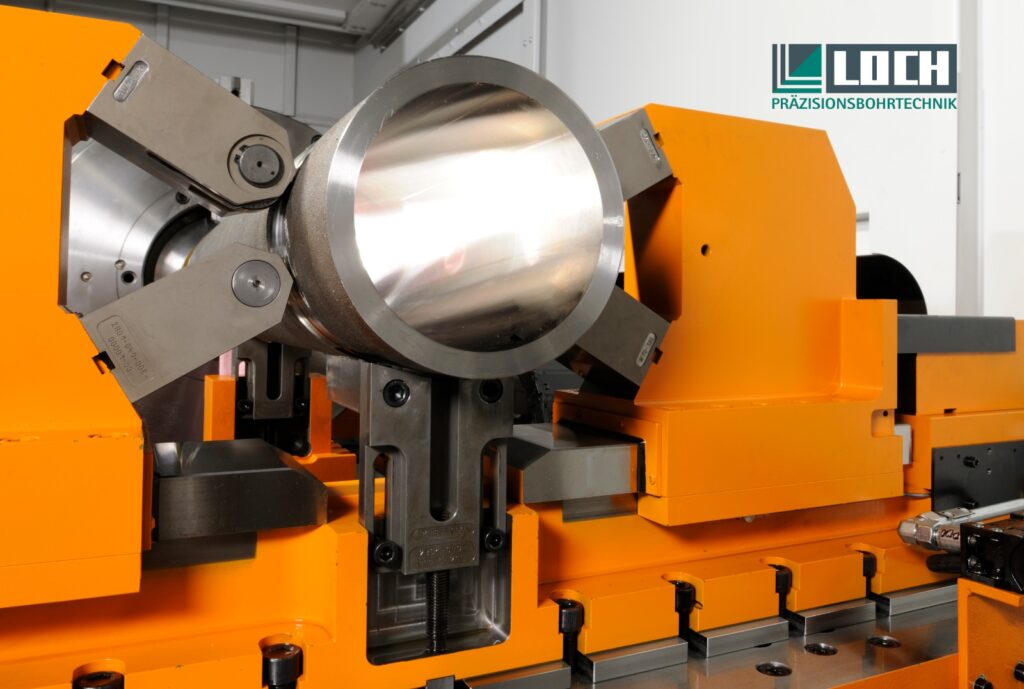

Deep hole drilling machines type TB2 / TB4

1-axis machines for the production of medium and bigger drilling diameters.

Also available in two-spindle configuration, on request.

01 Production system

BTA / Ejektor

02 Production method

- Stationary tool, rotating workpiece

- Rotating tool, stationary workpiece

- Turning tool, counter-rotating workpiece

03 Solid drilling

15 – 250 mm

04 Counterboring

Up to 400 mm

05 Drilling depth

Up to 12.000 mm

06 Optional available

- A conversion kit for honing

- A conversion kit for bottle boring

- A conversion kit for skiving and roller burnishing

- Configuration for automatic loading and unloading

Coordinate deep hole drilling machine

01 Production system

ELB / BTA

02 Diameter range

- 1-80mm, on request sizeable diameter possible

- Machining depth (axis Z): up to 2000 mm

- Horizontal shift of the workpiece (axis X): +/- 2500 mm

- Vertical processing of the drilling unit (axis Y): up to 1500 mm

- Motion of the workpiece to to the drill unit up to 500 mm

- Rotary indexing table (axis B): 360°

- Swiveling the drill unit (axis A) : +30° -10°

03 Optional available

- Automatic tool changer

- A conversion kit for honing

- A conversion kit for bottle boring

- Configuration for automatic loading and unloading

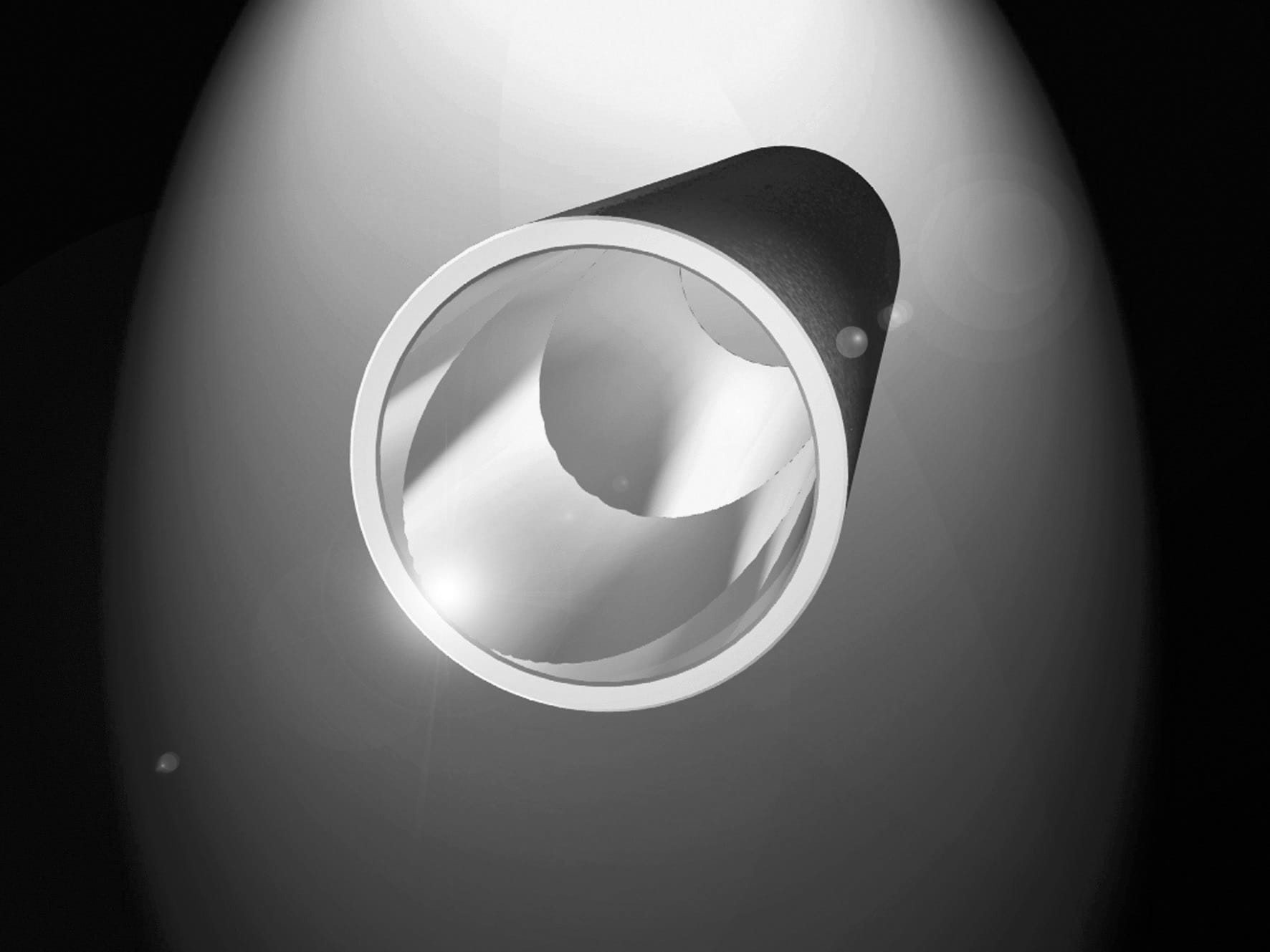

Cylinder processing machines

01 Production system

Combined tools for the processing of cylinder tubes

02 Diameter range

20 – 500 mm (dependent on tools)

03 Drilling depth

Up to 12.000 mm

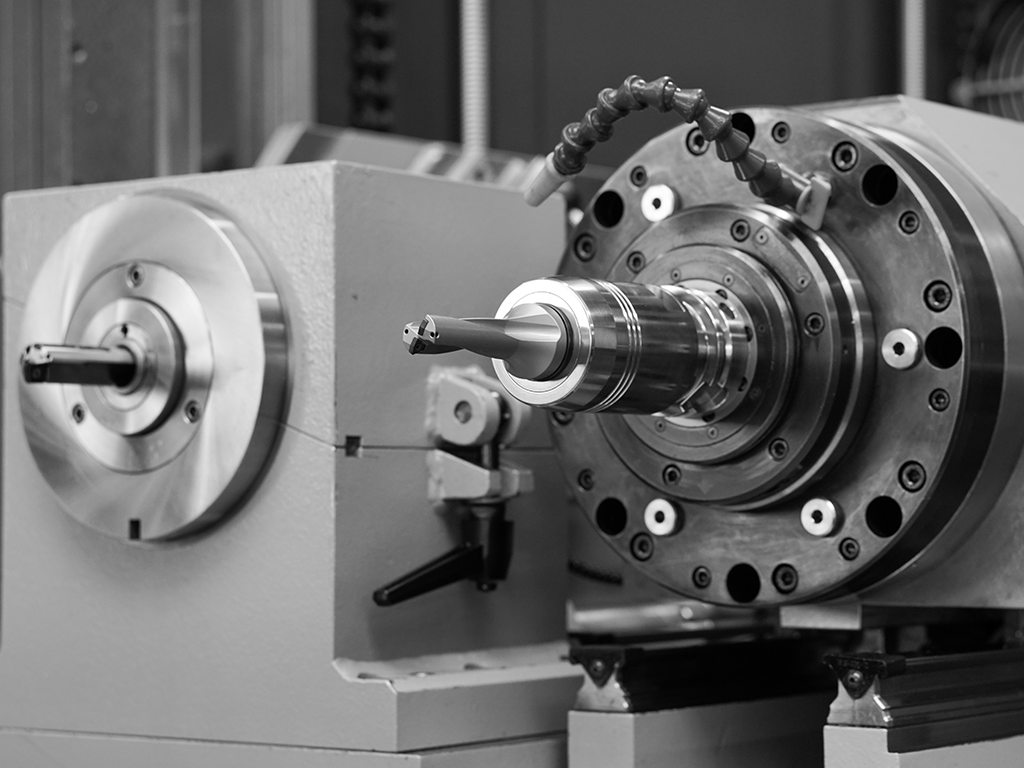

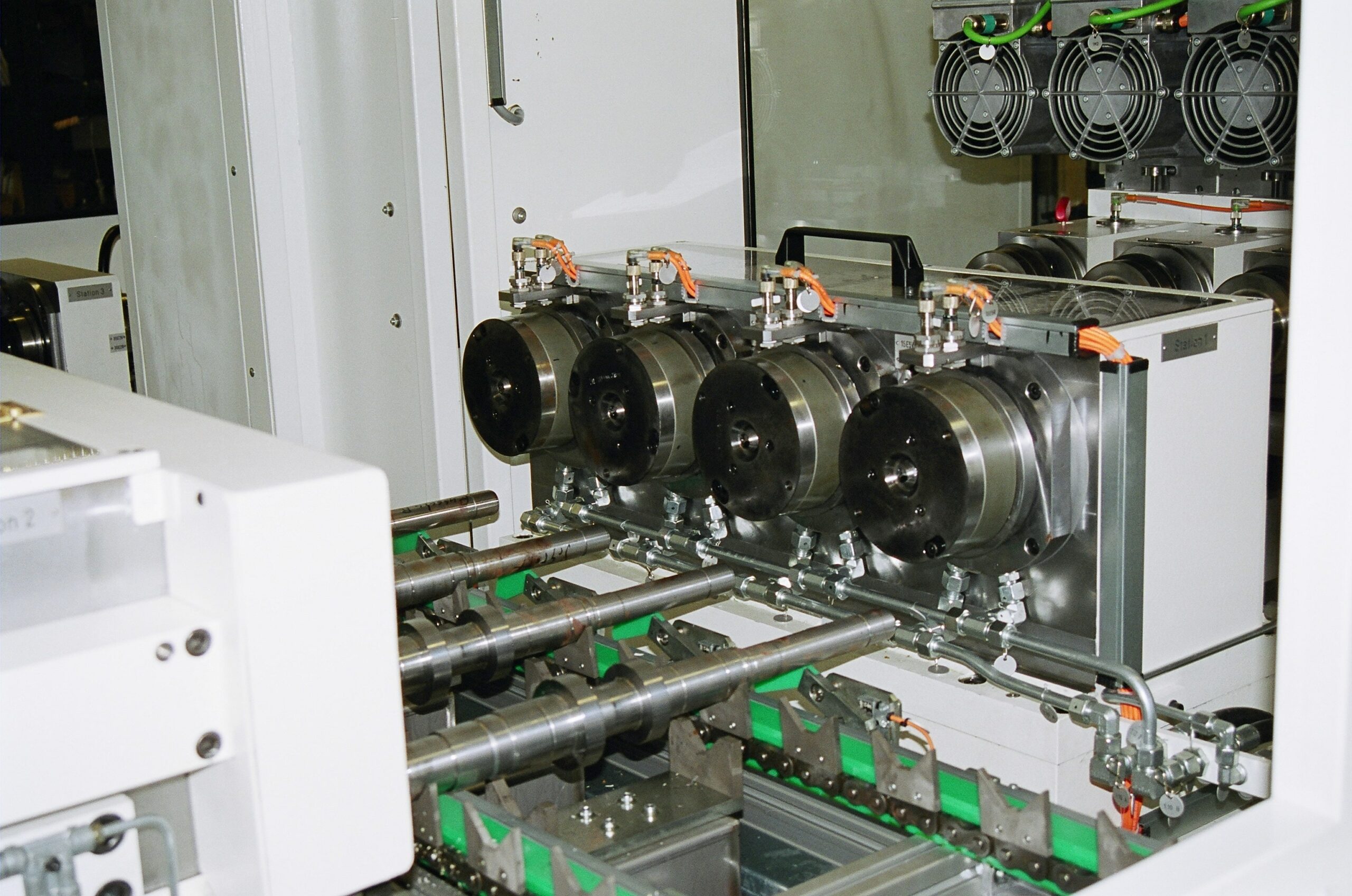

Deep hole drilling plants

Automated plant consisting of more spindles for the deep-hole drilling of

large-scale products.The design of the plant allows a multi-stage drilling

process.The adapted but flexible loading / unloading systems allow a

signifacant reduction of the auxiliary process time and therefore an

enormous increase in the productivity.

01 Production system

ELB / BTA

02 Additional processing possible

For example: Counter-drilling, honing, threading, deburring and bottle boring